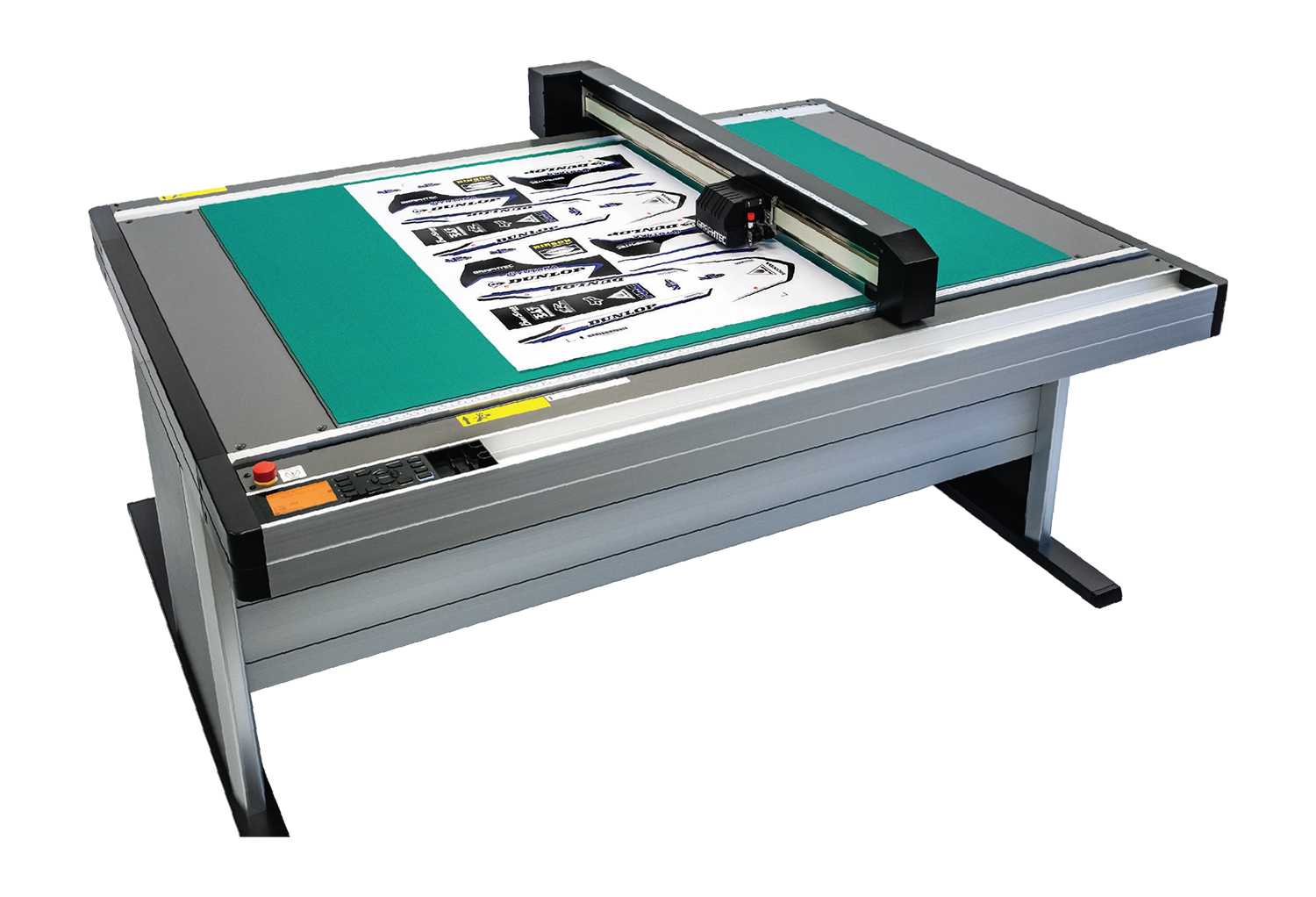

Users are empowered to create custom orders at low cost with short delivery times. Redesigned Y bar and cutting table deliver high precision cutting and creasing. New dedicated design software and plug-ins provide all of the tools necessary to create elegant, professional products.

Dual head design delivers 500G and 1000G of force at speeds up to 400mm/s.

Process materials thick or thin including: Rubylith, Static Cling Film, Vinyl, Rubber Sandblast, Diamond Grade Reflective, Chipboard, E-flute and more.

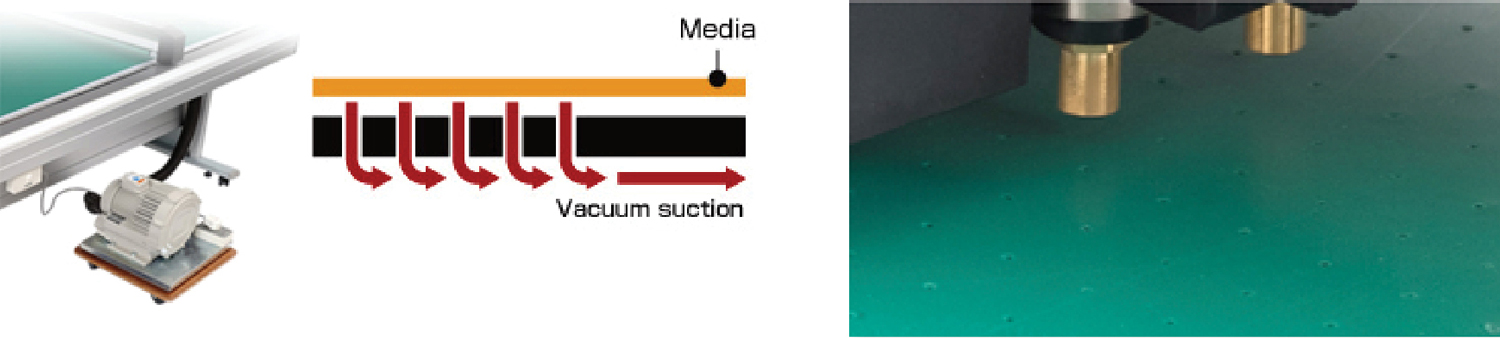

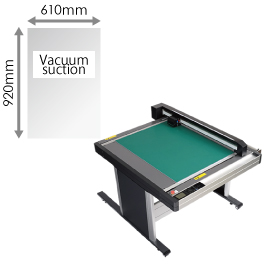

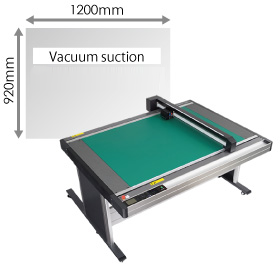

Three table sizes of 24 x 36”, 48 x 36” and 70 x 36” are available utilizing enhanced vacuum suction media hold down.

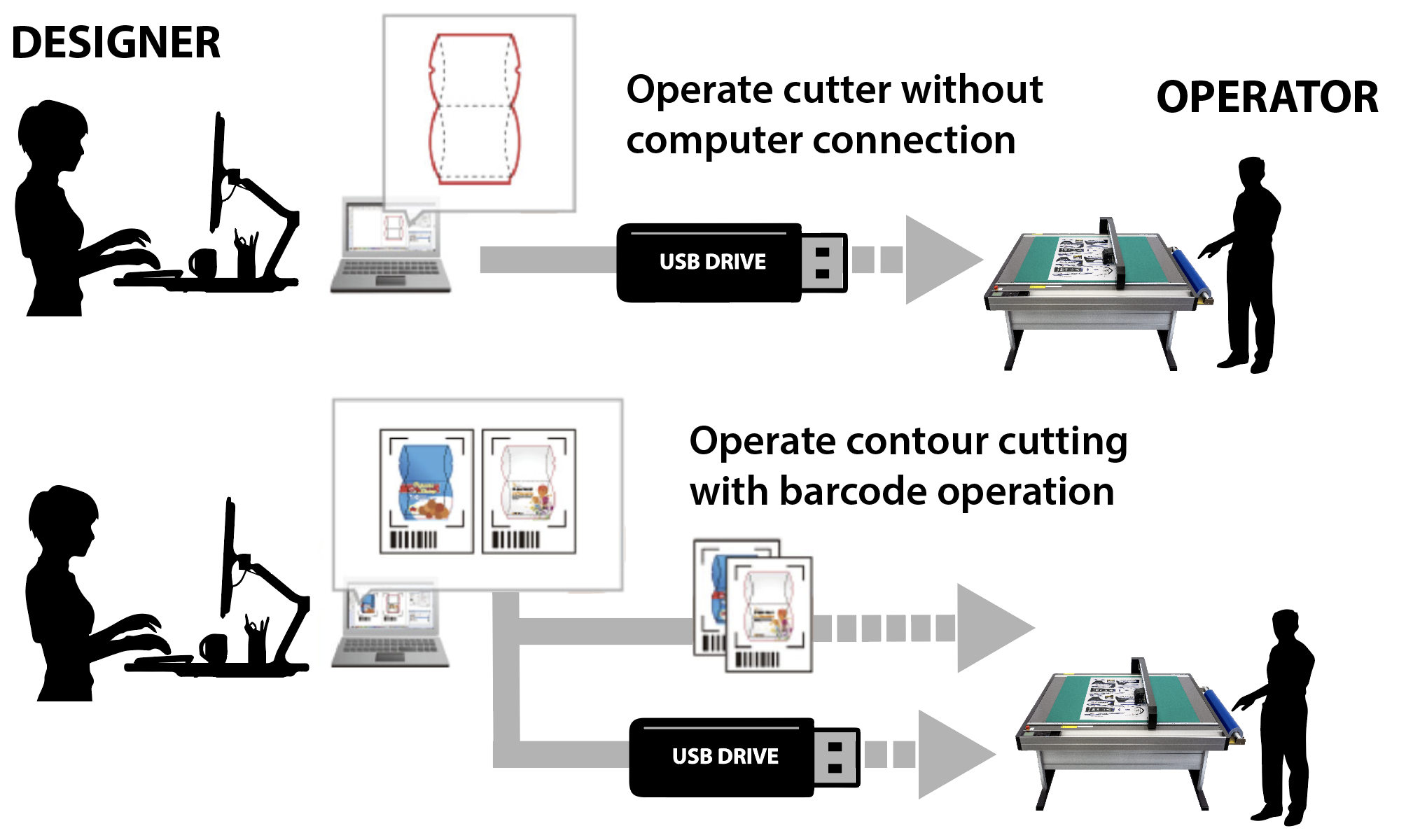

With Offline USB Operation, individuals with minimal experience can operate the machine directly without requiring a computer. USB operation allows operators of all skill levels to handle various types of media for cutting. Once the designer has created the plot file, it can be shared with users of any experience level to produce. All that is needed is to insert the USB and select the file from the user-friendly 3.7 inch Graphic LCD screen. The cutting conditions are automatically applied, and the job is executed. Additionally, barcodes can be generated for print and cut applications. The cutting data is automatically selected from the USB flash memory by scanning the barcode printed on the media, allowing for seamless contour cutting and reducing the possibility of operator errors.

The FCX2000 Series is equipped with Graphtec’s renowned ARMS system (Advanced Registration Mark Sensing) technology that allows users to accurately contour cut pre-printed graphics with ease. Auto-scanning of four point registration marks compensate for distortion in both X & Y directions to ensure precise cutting. Version 6.0 is packed with high productivity features such as ARMS Copy, One Point Compensation, Scan Start Position, and Expanded Cutting Area capability.

Graphtec’s Cutting Master 4 plug-in for Adobe Illustrator and CorelDRAW is used to send cut designs, as well as control parameters of the plotter. This is where registration marks can be added, large designs tiled; matrix copies created, and weed lines added. Graphtec Pro Studio design software offers an array of design tools and extensive file format compatibility – including EPS, CMX and PDF. In addition, Graphtec Pro Studio PLUS is an upgrade to unlock advanced features such as true shape nesting, arranging the cut order of objects, and rhinestones.

Interface: Ethernet, USB2.0 and Serial RS-232C | Intuitive 3.7” LCD Screen | Digital Servo Motor USB Flash Memory for Offline Operation | Win & Mac Compatible

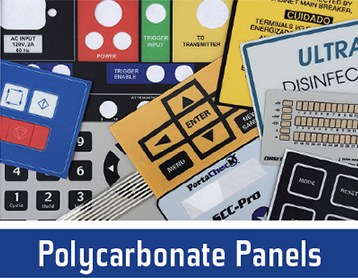

Applications

Features

Dual Tool Holder – Tool 1: 500GF | Tool 2: 1000GF

Provided tools suitable for multiple applications

The FCX2000 has 2 Tool Holders in the Carriage.

Using 2 different tools allows you to do 2 different jobs without exchanging tools, which increases work efficiency.

Use cutting and creasing tools together

Dual Tool Holders which can hold a cutting blade and creasing tool to produce creases/folds and cuts on the same run.

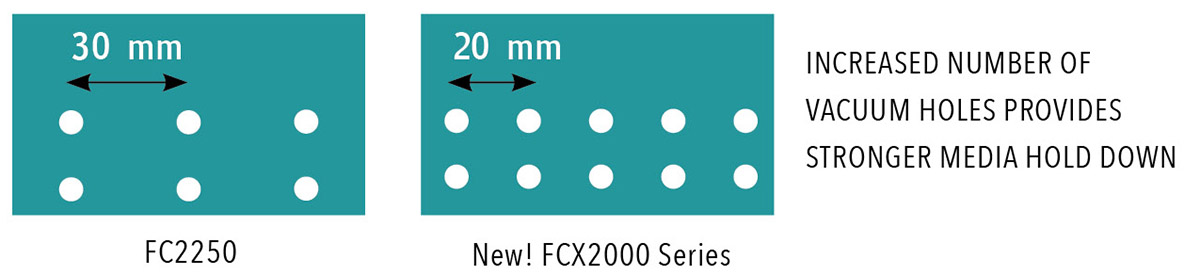

Stronger media hold-down

Distance between the holes has been improved from 30 mm on FC2250 Series to 20 mm on FCX2000 Series, as a result, FCX2000 Series provides stronger suction power to hold heavier and thicker medias down.

Intuitive operation with 3.7″ lcd

Onboard control and settings are simplified using the equipped 3.7” LCD (240×128 dots) and tactile control panel.

Improved Y-bar Rigidity: For precision cutting accuracy

Safety enhancement: A new, dedicated emergency STOP switch is at the ready.

Supports a dedicated stop switch for stopping the machine when emergency case is occurred.

Roll-media stocker: The FCX2000 comes equipped with a mounted roll-media stocker.

Supports media width up to 37.4” and weight up to 11 lbs.

Offline operation using usb thumb drives

Cut and plot data is created with Cutting Master 4 or Graphtec Pro Studio software. The saved data may be transferred to a USB Thumb Drive and the cut plot data file can be selected from the USB on the FCX2000 using its menu operations. This simplified work-flow enables users to operate without being connected to the computer.

Data Management using Bar-code Function with USB flash memory

When performing contour cutting, also known as “Print & Cut”, the cutting data is automatically selected from the prepared USB flash memory. The FCX2000 scans the bar code printed on the media then automatically performs the contour cutting job. This emerging method helps to prevent operator error of using incorrect data – thus improving workflow efficiency.

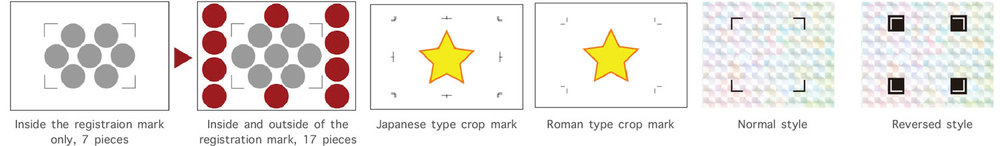

Expanded Contour Cutting Area

This included function expands the print and cut area to include objects outside of the registration marks! Production efficiency is enhanced and media waste is reduced.

Supports Standard Crop Marks

Contour cutting pre-printed media is also possible using “standard crop marks.” This operation is available with the included Cutting Master 4 plug-in workflow.

Reversed Color Registration Marks

Registraiton marks are detectable when there is sufficient contrast against the mark and its background. Ultra glossy and reflective media offer challenges for accurate registration mark detection. With this reversed color output, the sufficient contrast is brought back for the ability to contour cut pre-printed ultra glossy and reflecting sheeting.

Reviews

There are no reviews yet.